When ordering your timbers from a local sawyer, they will more than likely be fresh cut and “green” with a high moisture content. Before using these timbers in your construction, they should be air dried for a time. This will lower the moisture content of the wood and helps to ensure the stability of the wood after construction. Air drying of lumber has to be done properly or you will end up with wood that is not of high quality or even damaged beyond repair. To air dry lumber you need to make sure that it is kept both dry and with good airflow.

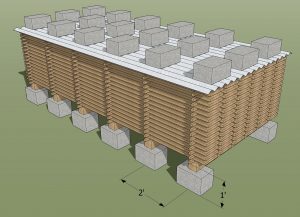

When building a stack of drying lumber you will always want to keep the wood off the ground. I like using concrete blocks for this as they are relatively easy to move around and can stand up to the weight of a pile of lumber. When placing the concrete blocks you are building what looks like a grid with the blocks spaced two feet apart. The width of the stack should be whatever you are comfortable with (I typically build four feet across) and the length should be determined by your longest lumber pieces. When laying out the concrete blocks you need to work to ensure that they are level. Use a four foot level placed between the blocks as you are laying them out to ensure that you will have a flat surface. Once you have the concrete blocks laid out you will need pieces of lumber (preferably already dried) laid across the blocks in “rows” to provide support for the stack between the blocks. I will typically use four foot long 2x4s that I keep around for this purpose.

Keeping wood dry can be done a variety of ways but to ensure airflow in a pile of lumber you need to use “stickers”. Stickers are pieces of wood that ideally be cut from the same species of wood as your timbers. They are typically three-quarters of an inch high by an inch and a half wide and the length should be the width of your stack of lumber. Space the stickers every two feet down the lumber (directly above a concrete block) and make sure you have stickers near the ends of the timbers. With an eight foot board that would mean you would use five stickers. Your sawyer shoul d include stickers in your order but it would be best mention them when setting up the order to ensure they will be included up front.

When building your stack of lumber for drying it is best to begin with the smaller pieces on the bottom. The heavier timbers on top should ensure there is enough weight to help with keeping the wood flat as it dries. I have seen 4x4s curl like a bow and even 6x6s will twist sometimes so the more weight the better. Finally, you will probably want to put some weights on top of the stack to help keep the top lumber from warping. You might need to place a piece of plywood or tin on top of the stack in order to spread the weight on top.

Ideally wood is completely protected from the elements. Often this arrangement is neither practical nor possible. If this is the case, you will want to minimally cover the top of the drying stack of wood with something like roofing tin to keep the rain off. If rain gets on the sides it will slow the drying progress and could potentially cause issues with molding.

What is the moisture level that you are trying to achieve? The acceptable moisture level for wood is generally six to eight percent for wood flooring, six to nine percent for furniture, and nine to fourteen percent for construction. Measuring the level of moisture is done using a moisture meter. If you are going to be using “green” lumber from a sawmill then a good moisture meter is probably going to needed. I bought this meter seven years ago and it is still working very well.